As I write this, sat with my morning coffee, something has just mysteriously popped in the kitchen. It's a bottle of slowly fermenting apple juice, destined to become cider vinegar for the chickens. Sue squeezes the bottle in to allow room for the gases to expand and every now and again the plastic pops back out.

|

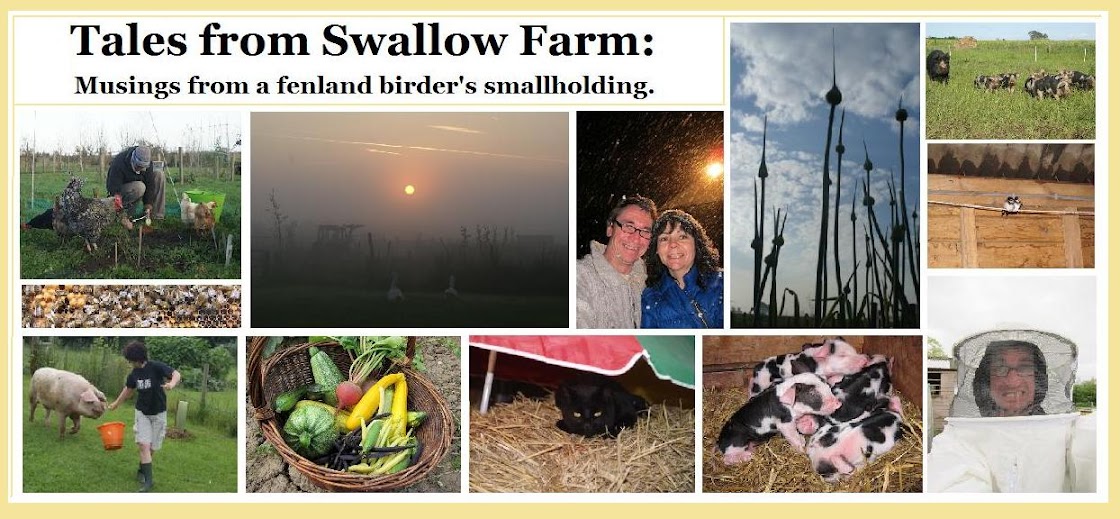

| Cider making day - The team at work. |

|

| Chopping |

|

| The process known as "scratting" |

|

| smaller... |

|

| and smaller... |

|

| and smaller. |

As the production line moved towards its end, I became more involved in operating the press. This is a beast of a machine, pretty much cobbled together from recycled and scrounged materials, but it exerts quite some pressure and the juice soon starts to flow out of the pulp. It reminds me of a medieval torture machine and brings new meaning to turning the screw.

|

| SQUEEEEEEEEEZE!!!! |

So, how do we turn the juice into cider?

Well, once we've got it home it's decanted into clean demijohns (the big glass containers with a narrow neck, readily available on ebay etc) and there it sits. Leave a bit of space at the top. The only other equipment you need is a bung with an airlock. You half fill the airlock bit with water. This works similar to a u-bend! Any excess gases bubble up through the water and escape, but the fermenting apple juice is not exposed to the air outside. You don't need to add anything. After a few days, sometimes a bit longer, the juice starts to develop a froth on top and not much later you start to hear strange bubbling sounds. Look closely and you will see millions of tiny bubbles of gas rising through the fermenting juice. It's really quite astonishing how active it gets.

This continues for about a week and eventually it all settles down. The bubbling stops and the sediment starts to settle. Leave everything to settle completely, then syphon the liquid off into whatever bottles (sterilised) you're using. There may be further development of gases, so old lemonade / coke bottles are good for this, or proper beer bottles, either the Grolsch type or normal bottles if you have a bottle topper.

Of course, it can be a bit more complicated than this. You can measure the specific gravity of your fermented juice, you can sweeten it, you may experience secondary fermentation (!). But, at the end of the day, we don't mind how it turns out as long as it's drinkable. Sometimes it's sweet, sometimes it's dry. Sometimes it's still, sometimes it's fizzy. To tell the truth, we don't know why. It just happens and it's always a good moment to find out how a batch has fared.

Of course, if you want to be more scientific and control the outcome a bit more, you can read up on it elsewhere. But the basics as outlined here should get you a fairly decent tipple.

None of the equipment costs very much. By far the most expensive is the press, if you're buying a new one. Pulverising the apples can be a bit of a chore too and you can buy various machines to do this for you. The best will set you back in the region of £700! You'd have to drink a lot of cider to make this worthwhile. Of course, you could always start up your own cider club. It certainly makes for a very pleasant day.